Biomass Grinding Efficiency Brought into the 21st Century

Patents 61538451, 6131838 and 9090041

Processing biomass waste 8 hours a day 6 days a week takes dedication with the right grinding equipment and dedicated replacement teeth (parts) to optimize operating hours.

Every 4 hours visual checks of the rotor components and their effectiveness are good sops to monitor the wear of the components on the rotors to keep production tonnages at their peak performance standards.

When an operator sees production falling and can observe (during his 4-hour inspection) cutting edges (grinder tips) need to be replaced normally in 35 seconds for each tip with Production Plus top tips replacement it should not be a 2 or 3 hour down time to do the following:

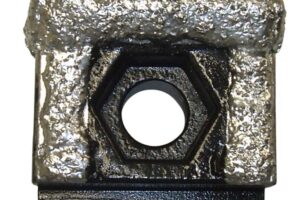

Flip the tip end to end, replace the entire tip as both edges are worn out. Or save a partial worn out tip and move it to another location on the rotor. Regardless, it is mandatory to loosen and replace 2 bolts on each tip and even more time if you are moving a partially worn tip to a new location on the rotor.

Replace only the cutting tip (top half) that is worn out. 35 seconds (that is right, only 35seconds) to change the cutting edge you can now run that top tip in that location on the rotor and then throw it away. (No moving tips to other location on the rotor.)

When the material being processed changes to “big wood” or “chunked pieces” you can now replace the top cutting edge with a sharp edge tooth without changing the entire two bolt tip. You might select to run a combination of standard tips and some or all sharp edge tips.

Whatever it takes to optimize the production level and desired product size. All at 35 seconds change time per hammer. Not hours.

You asked about replacing the bottom pusher blocks – great question! History reports from satisfied customers. You normally (depending on how dirty your grinding is) will replace 4 to 5 top tips on each hammer, before you change out the bottom pusher block.

We recommend at least once a month, or sooner as required, The bottom pusher blocks are replaced as needed, some positions on the rotor may require more attention than others to keep the rotor at the top performance standard.